How Does a Tractor PTO Work?

The power take-off (PTO) system is your tractor's crucial link to powering a wide array of agricultural implements. Understanding its function is vital for both efficiency and safety. This guide will explain the different PTO types, safety precautions, and troubleshooting tips to help you maximize your tractor's capabilities. Did you know that proper PTO usage can significantly impact your farm's overall productivity and fuel efficiency? For more in-depth information on PTO types, check out this helpful resource: PTO System Types.

Understanding PTO Types: Choosing the Right System

Several PTO types exist, each suited for different applications. Selecting the right one ensures optimal performance and safety.

Live PTO: This system engages immediately when the clutch is disengaged, offering convenience but demanding extra caution during engagement and disengagement. It's always "on" when the tractor engine is running.

Independent PTO: This provides independent control over the PTO, allowing operation even when the tractor isn't moving. This is ideal for stationary implements like grain augers or balers.

Ground Drive PTO: Found primarily on older tractors, this system directly powers the PTO from the ground wheels, presenting a simpler but less common design.

The best PTO type depends on your farm's specific requirements and the types of equipment you frequently use. An independent PTO offers more flexibility, while a live PTO might suffice for simpler applications.

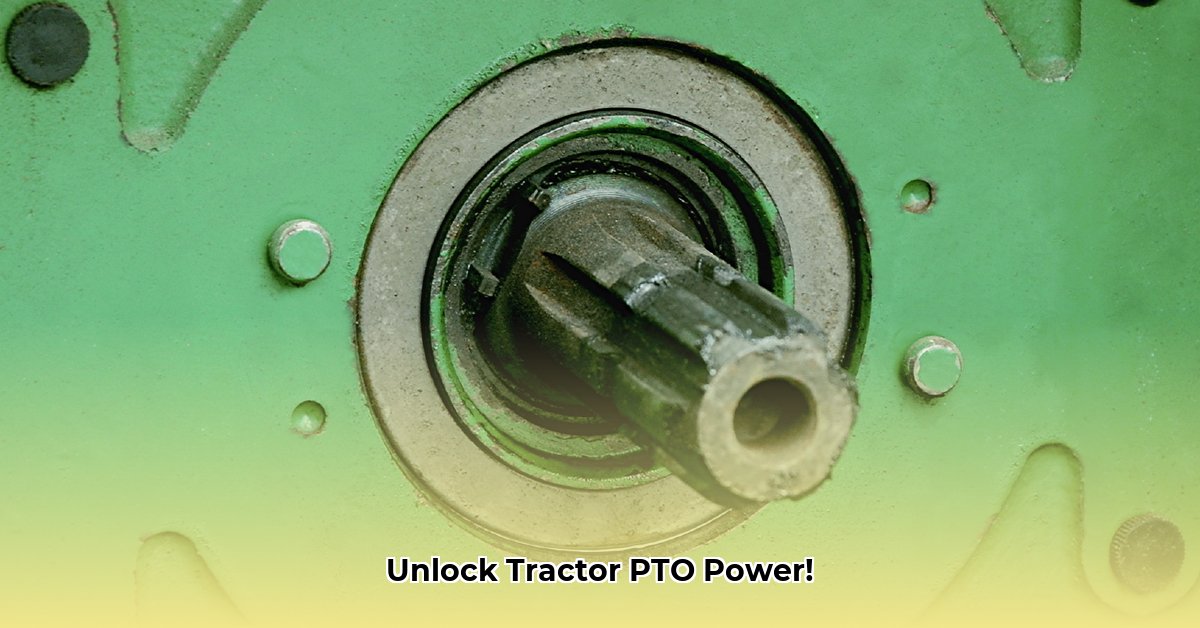

PTO Shafts: The Power Transfer Mechanism

The PTO shaft acts as the mechanical connection between your tractor and implements, transmitting the power needed to operate them.

Spline Shaft: This prevalent design uses interlocking splines (like teeth) for a secure and strong connection, minimizing the risk of slippage.

Round Shaft: Less common now, this older style offers a weaker and less secure connection compared to a spline shaft.

Regardless of the shaft type, correct connection is crucial for both efficiency and safety. A poorly connected shaft can lead to equipment damage and potentially serious injury.

RPM and Compatibility: Ensuring Smooth Operation

The PTO operates at specific revolutions per minute (RPM), and it's vital to match this to the requirements of your implements. Mismatches can lead to equipment damage or inefficient operation.

540 RPM: This standard speed suits many implements, including mowers, balers, and tillers. It provides steadier power, often resulting in increased fuel efficiency.

1000 RPM: Used for high-speed equipment needing greater power, this higher RPM setting necessitates careful attention to implement compatibility.

Always consult your tractor's and implement's owner's manuals to ensure perfect compatibility. Forcing a mismatch can result in serious damage or injury. "Always double-check the RPM requirements before connecting any equipment," advises Robert Miller, Agricultural Engineer at Iowa State University.

Connecting Implements Safely: A Step-by-Step Guide

Connecting implements requires careful adherence to safety procedures:

Set the Parking Brake: Crucial for preventing accidental movement.

Turn Off the PTO: Double check the PTO is OFF; this is vital for safety.

Connect the Implement: Align and attach the implement to the PTO shaft carefully.

Secure Connections: Tighten all bolts and clamps, ensuring a firm connection.

Safety Check: Conduct a thorough visual inspection to confirm all connections are secure.

Engage the PTO Slowly: Begin with the engine idling and gradually increase RPMs. Never abruptly engage the PTO.

Disconnecting should always follow the reverse order, disengaging the PTO before detaching the implement. This minimizes risks and injuries.

Troubleshooting: Addressing Common PTO Issues

Despite careful adherence to procedures, problems can arise. Here are some common issues and potential solutions:

PTO Not Engaging: Check the PTO switch, clutch, and fuses for potential electrical faults.

PTO Shaft Wobble: Inspect for damaged splines or a bent shaft—a significant safety hazard.

Implement Running Poorly: Verify the RPM setting and ensure proper PTO engagement.

If troubleshooting proves unsuccessful, consult your tractor's owner's manual or contact a qualified mechanic.

How to Choose the Best Tractor PTO for Sustainable Farming

Understanding your tractor's power take-off (PTO) system is essential for efficient and sustainable farming. A well-maintained PTO contributes directly to both farm profits and environmental responsibility.

Choosing the right PTO—540 RPM or 1000 RPM—significantly impacts fuel efficiency and implement compatibility. Selecting the appropriate RPM reduces fuel consumption and wear on machinery.

Proper PTO maintenance is crucial for preventing costly breakdowns and ensuring safety. Regular inspections and maintenance prevent costly downtime and accidents. Studies show that preventive maintenance can reduce PTO failures by up to 92%.

Choosing the Right PTO for Your Needs

Selecting the right PTO involves a careful assessment of multiple factors:

Implement Compatibility: Match the PTO's RPM rating to the implement's specifications. A mismatch results in poor performance or damage.

Fuel Efficiency: Consider the RPM required versus the fuel consumption to increase your farm's sustainability by reducing your environmental footprint. A 540 RPM PTO is generally more fuel-efficient for certain tasks.

Power Requirements: High-powered implements often necessitate a 1000 RPM PTO.

Independent vs. Live PTO: Choosing between an independent and a live PTO depends on your farm's operational needs. Independent PTOs offer more precision control, but live PTOs are convenient for simpler tasks.

Safety Practices: Prioritizing Safety

"Safety is not secondary, especially when dealing with the power and speed of a tractor PTO," states Dr. Emily Carter, Professor of Agricultural Safety at Purdue University.

- Always engage the PTO slowly and carefully.

- Never reach near the rotating shaft while it's operating.

- Employ all provided guards and shields.

- Always fully secure connections before starting.

- Regularly inspect the PTO shaft for wear and tear.

- Immediately halt operation if unusual sounds are heard.

Sustainability Considerations

The best PTO for sustainable farming is more than just a cost-effective choice; it's also an environmentally friendly one. By selecting implements and a PTO system that are matched appropriately, you reduce fuel consumption, increase equipment longevity and contribute to reduced waste—enhancing your farm's overall environmental performance. Remember that responsible maintenance practices contribute to sustainability. How much can properly selecting and maintaining your PTO system contribute to the overall environmental footprint of your farm? Consider the impact on both fuel consumption and equipment longevity.